HOMETECH☰

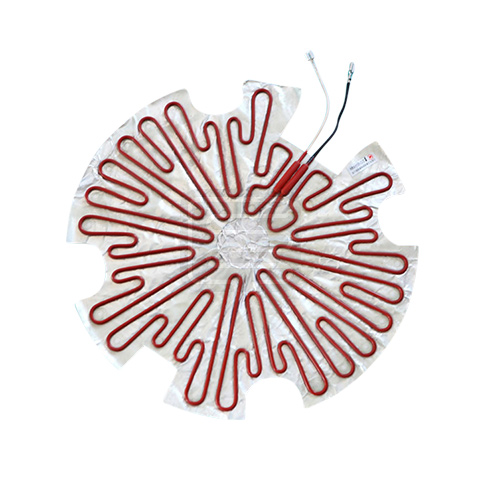

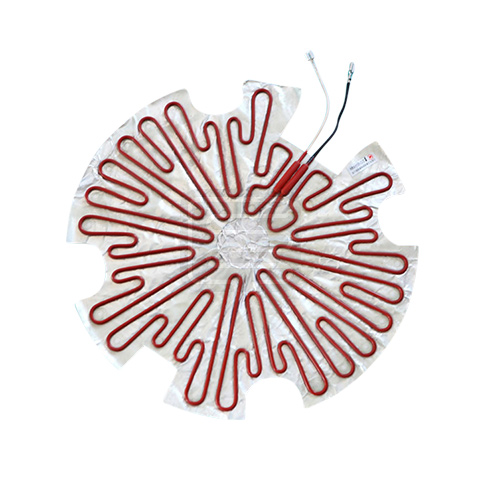

The aluminum foil composite Heater is a sheet heater composed of aluminum foil as a heat transfer carrier, and the Heating Wire is bonded to the aluminum foil through an auxiliary adhesive. In terms of structure, it can be divided into double-layer aluminum foil glue type and single-layer aluminum foil hot-melt type. The Heating Element can be PVC or silicone insulated heating wires. The heating wire is placed between two sheets of aluminum foil or heat-fused to a single layer of aluminum foil. There is double-sided adhesive tape on the back of aluminum foil heater, this allows for it to be conveniently, quickly and easily installed on the heated surface that requires temperature control. Aluminum Foil Heaters are customized on demand, with various sizes, adhering to Safety standards, uniform heat transfer attributes, waterproof and moisture-proof, long lifespan and low price.

Aluminum foil composite Heating Cable/heater is suitable for applications where the rated voltage is below 250 V, 50-60 Hz, relative humidity of 90%, and ambient temperature of -30~+50 ℃. Its large surface area, uniform heating and ease of use, allows it to be widely used for defrosting and thawing of Refrigerators, Freezers, etc.; anti-freezing of Plate Heat Exchangers; maintaining the temperature of hot food counters in restaurants; prevent condensation of electronic and electric control Boxes; heating of sealed compressors; prevent condensation on bathroom glass, refrigerated display case condensation; household products, heated medical supplies, intelligent temperature controlled toilet seats, medium and low temperature surface heating and insulation, such as Rice Cookers, incubators, printers, dryers, insulation rooms, Toasters, Electric ovens, beauty appliances, door and window defogging, etc.

| Classification | PVC | GJ | |

| Heating wire insulator | 105℃PVC | Silicone Rubber | |

| Dimension | Can be customized | ||

| Voltage | According to needs | ||

| Output | Up to 2.5KW/m2 | ||

| Power deviation (resistance value deviation) | ≤±5% | ||

| Normal Insulation Resistance | ≥100 MΩ | ||

| Water immersion voltage resistance | 1800V/min, or 2200V/5s without puncture or flashover | ||

| Current Leakage under working temperature | ≤0.12 mA | ||

| connection strength | Heating wires and lead wires | ≥36N 1min No abnormality | |

| lead Wires and Terminals | ≥58.8N 1min No abnormality | ||

| Heating wire and aluminum foil hot melt adhesive strength | 400g/ 1min No abnormality | ||