HOMETECH☰

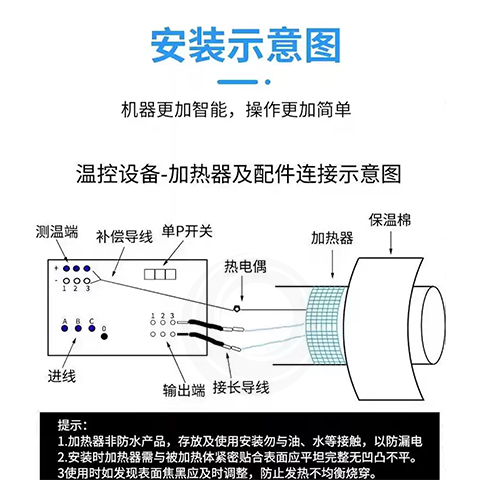

Ceramic Pad Heaters use high-quality nichrome wire cable as the heating body and high-strength alumina ceramic components with good thermal radiation performance as the insulation layer. The nickel-chromium wire cable and electric wire are welded by a new technology. All the welded joints are buried in the ceramic components to ensure reliable insulation. The ceramic pad Heater and control equipment become a complete heat treatment system. All components are connected using special Connectors and can be configured with extension leads depending on the distance between the components and the control devices.

the ceramic pad heater is applicable to various metal components, such as large towers, high-pressure vessels, bridges, welding preheating of high-pressure pipelines, and post-welding stress relief, and can also be used for chemical pipelines, vessels and other auxiliary heating. It is an ideal product for localized heating.

Pad Heaters can be assembled on stainless steel brackets and ceramic insulation Pads (or just insulation Pads), or you can use magnet brackets with High-Temperature resistance.

1. 98% alumina ceramic components

2. Ni/Cr-80/20 electric resistance wire

3. Maximum working temperature 1050°C

4. Max. current 50A

Made of high-quality nickel-chromium alloy wire and cable, the outer set of high-purity alumina ceramic insulation parts is made into the body of Pad. The length and width can be changed flexibly and produced according to the shape and size of the workpiece. It can be spliced, bent, or wound around the workpiece for heating. With a wide range of use, fast heating speed, high heat utilization rate, and energy-saving qualities, it significantly lowers labor intensity and is easy to operate.

Depending on the geometry of the workpiece, wall thickness, and heat treatment process requirements, one can choose the corresponding specifications.

The following table shows only some of the specifications, which can be customized.

| Model | Heating size(mm) | Working voltage (V) | Rated power (kw) |

| Bendable side * straight side | |||

| LCD | 680×340 | 220 | 10 |

| LCD | 880×260 | 220 | 10 |

| LCD | 1020×220 | 220 | 10 |

| LCD | 1160×200 | 220 | 10 |

| LCD | 1360×160 | 220 | 10 |

| LCD | 1860×120 | 220 | 10 |

| LCD | 500×450 | 220 | 10 |

| LCD | 420×530 | 220 | 10 |

| LCD | 500×220 | 110 | 5 |

| LCD | 420×260 | 110 | 5 |

| LCD | 600×180 | 110 | 5 |

| LCD | 260×200 | 55 | 2.5 |

| LCD | 420×120 | 55 | 2.5 |

| LCD | 75×660 | 60 | 2.7 |

| LCD | 100×495 | 60 | 2.7 |

| LCD | 150×330 | 60 | 2.7 |

| LCD | 205×250 | 60 | 2.7 |

| LCD | 255×205 | 60 | 2.7 |

| LCD | 305×165 | 60 | 2.7 |

| LCD | 380×145 | 60 | 2.7 |

| LCD | 405×125 | 60 | 2.7 |

| LCD | 535×100 | 60 | 2.7 |

| LCD | 610×85 | 60 | 2.7 |

| LCD | 1220×45 | 60 | 2.7 |

| LCD | 255×85 | 30 | 1.35 |

This product is an enhanced version of the pad heater, which is designed with a more reasonable power density and therefore has a longer lifespan than the general pad heater. It has the exact scope of application and usage as the LCD pad heater.

| Model | Heating size(mm) | Working voltage (v) | Rated power (kw) |

| Bendable side * straight side | |||

| LCDJ | 680×450 | 220 | 8 |

| LCDJ | 860×340 | 220 | 8 |

| LCDJ | 1020×300 | 220 | 8 |

| LCDJ | 1160×260 | 220 | 8 |

| LCDJ | 1360×220 | 220 | 8 |

| LCDJ | 500×610 | 220 | 8 |

| LCDJ | 500×300 | 220 | 4 |

| LCDJ | 420×370 | 220 | 4 |

| LCDJ | 260×260 | 110 | 2 |

The pad-type ceramic Electric Heater is made of a new type of porcelain block which is much easier to bend. It is specially used for preheating before welding and annealing after welding of pipes.

| Model | Heating size (mm) | Applicable pipe diameter(mm) | Working voltage (v) | Rated power (kw) |

| LCDG | 130×180 | φ33 | 36 | 1.6 |

| LCDG | 160×160 | φ42 | 36 | 1.6 |

| LCDG | 170×140 | φ48 | 36 | 1.6 |

| LCDG | 210×180 | φ60 | 55 | 2.5 |

| LCDG | 270×300 | φ76 | 110 | 5 |

| LCDG | 310×260 | φ89 | 110 | 5 |

| LCDG | 360×220 | φ108 | 110 | 5 |

| LCDG | 440×180 | φ133 | 110 | 5 |

| LCDG | 510×160 | φ159 | 110 | 5 |

| LCDG | 710×330 | φ219 | 220 | 10 |

| LCDG | 880×260 | φ273 | 220 | 10 |

| LCDG | 1040×220 | φ325 | 220 | 10 |

| LCDG | 1170×200 | φ377 | 220 | 10 |

| LCDG | 1360×170 | φ426 | 220 | 10 |

The heater is equipped with insulation pad and a shell to transform it into a self-insulating flat plate heater, which is very convenient to use.

| Model | Heating size(mm) | Working voltage (v) | Rated power(kw) |

| Bendable side * straight side | |||

| LCDP | 680×340 | 220 | 10 |

| LCDP | 880×260 | 220 | 10 |

| LCDP | 1020×220 | 220 | 10 |

| LCDP | 1160×200 | 220 | 10 |

| LCDP | 500×450 | 220 | 10 |

| LCDP | 420×530 | 220 | 10 |

| LCDP | 500×220 | 110 | 5 |

| LCDP | 420×260 | 110 | 5 |

| LCDP | 600×180 | 110 | 5 |

| LCDP | 420×120 | 55 | 2.5 |

For pipelines, pipe joints, angled pipes, and workpieces of various shapes, the narrow space makes it challenging to work around. A rope heater is particularly suitable for pipe joint heat treatment, boiler tube mouth heat treatment, etc.

| Model | Heating size(m) | Working voltage(v) | Rated power(kw) |

| SCD | 19 | 220 | 10 |

| SCD(Double row) | 9.5 | 220 | 10 |

| SCD | 9.5 | 110 | 5 |

| SCD | 4.7 | 55 | 2.5 |

| SCD | 4.7 | 55 | 2.5 |

| SCD | 1.85 | 24 | 1 |

| Model | Heating size(m) | Working voltage(v) | Rated power(kw) |

| SCDW | 9.5 | 110 | 5 |

| SCDW | 4.7 | 55 | 2.5 |

| SCDW | 2.3 | 24 | 1 |

A new type of ceramic bead is used, smaller or shorter than ordinary beads, and the rope heater is easier to bend and coil, which is especially suitable for heat treatment of pipes with small diameters.

| Model | Applicable pipe diameter(mm) | Working voltage(v) | Rated power(kw) |

| LCDQ | φ33 | 36 | 1.6 |

| LCDQ | φ48 | 55 | 2.5 |

| LCDQ | φ76 | 110 | 5 |

| LCDQ | φ89 | 110 | 5 |

| LCDQ | φ108 | 110 | 5 |

| LCDQ | φ133 | 110 | 5 |

| LCDQ | φ159 | 110 | 5 |

| LCDQ | φ219 | 220 | 10 |

| LCDQ | φ273 | 220 | 10 |

| LCDQ | φ325 | 220 | 20 |

| LCDQ | φ377 | 220 | 20 |

| LCDQ | φ426 | 220 | 20 |

With a pad heater as a heat source, coupled with insulation Paderial and a shell made into a circle-type folio heater, it is easy to install and disassemble. This is suitable for the local heating of small pipelines. The highest working temperature is 750℃.

| Model | Heating size(mm) | Working voltage(v) | Rated power(kw) |

| Bendable side * straight side | |||

| LCDX | 1160×200 | 220 | 10 |

| LCDX | 900×260 | 220 | 10 |

| LCDX | 620×200 | 110 | 5 |

| LCDX | 600×200 | 73 | 4 |

| LCDX | 600×200 | 60 | 3 |

The pad heater with a shell is installed with several magnets on both sides, which can be attached to the workpiece during heating. It is suitable for preheating metal components such as spherical tanks and ship hulls before welding. It is flexible and convenient to use. Ti is also ideal for welding preheating of steel components, welding preheating of steel plates, and welding preheating of large towers.

This heater can be arranged in the interior of large pressure vessels such as spherical and horizontal tanks for overall heat treatment of the workpiece. It can also be used as the Heating Element of large annealing furnaces. It is suitable for preheating steel plates, pit-type resistance furnaces, assembled resistance furnaces, vessel end heat treatment, etc.

| Model | Overall dimension (mm) | Working voltage (v) | Rated power(kw) |

| QZD | 1000×420×80 | 220 | 10 |

| QZD | 1100×380×80 | 220 | 12 |

The heater is made of a high-resistance alloy belt as a heating element, priced for its fast temperature rise, long life, and low voltage heating Safety. Combined with other Tooling, it can radiate heat to rotating workpieces. It is widely used in welding preheating and hot fitting processes of overfitting parts. The maximum temperature of the heating surface can reach 900℃, so it is suitable for preheating the inside and outside steel pipes, large heating rings, etc.

| Model | Overall dimension (mm) | Working voltage(v) | Rated power(kw) |

| HDOP | 620×410×80 | 36 | 5.5 |

| HDOP | 460×270×80 | 24 | 6 |

| HDOP | 540×270×80 | 24 | 6 |

| HDOP | 630×270×80 | 36 | 9 |

| HDOP | 590×340×80 | 36 | 9 |

| HDOP | 990×410×80 | 60 | 11 |

| HDOP | 930×340×80 | 60 | 14 |

| HDOP | 760×410×80 | 60 | 14 |