HOMETECH☰

Constant power heat tracing cable is a traditional Electric Heater using resistance wire heating.

The constant power heat tracing cable can be divided into parallel constant power heat tracing cable and series constant power heat tracing cable according to the structure.

The resistance wires of the parallel constant-power heat tracing cable are connected in parallel. When working, the resistance wire generates heat to heat the tube. Each parallel resistor generates heat, forming a continuous Heating Cable.

Single-phase parallel constant power heat tracing cable is mainly used for Process Heating of various pipelines and equipment. The maximum maintenance temperature can reach 180°C. It can be used for explosive gas occasions in Zone 1 and Zone 2 of the factory.

The power busbar is two parallel tinned soft copper wires, with nickel-chromium heating wires wrapped around the inner insulation, and the heating wires are connected to the busbar at certain distances (i.e., the "heating section length") to form a continuous parallel resistance. After the busbar is energized, each associated resistor generates heat, thus forming a continuous heating body. During use of the product, it can be spliced according to the length of the heating section.

| Model | Rated power per meter (W/m) | Max. service length (m) | The max. maintenance temperature of a fluid medium (°C) | Heating pitch length (mm) |

| TELX2 -J3/P F-1 0 | 10 | 400 | 180°C | 1760 |

| TELX2 -J3/P F-20 | 20 | 220 | 160°C | 1250 |

| TELX2 -J3/P F-30 | 30 | 150 | 140°C | 1040 |

| TELX2 -J3/P F-40 | 40 | 110 | 120°C | 880 |

Three-phase parallel constant power heat tracing cable is mainly used for process tracing of various pipelines and equipment. The max. maintenance temperature is 180°C. It can be used for explosive gas occasions in Zone 1 and Zone 2 of the factory.

The power busbar is three parallel insulated soft copper wires, with nickel-chromium heating wires wrapped around the inner insulation, and the heating wires are connected to the busbar at certain distances (i.e., the "heating section length") to form a continuous parallel resistance. After the busbar is energized, each associated resistor generates heat, thus forming a continuous heating body. During use of the product, it can be spliced according to the length of the heating section.

| Model | Rated power per meter(W/m) | Max. service length (m) | Max. maintenance temperature of fluid medium (°C) | Heating pitch length (mm) |

| TELX3 -J3 / PF-20 | 20 | 500 | 160°C | 1850 |

| TELX3 -J3 / PF-30 | 30 | 400 | 140°C | 1550 |

| TELX3 -J3 / PF-40 | 40 | 220 | 120°C | 1300 |

| TELX3 -J3 / PF-50 | 50 | 150 | 100°C | 980 |

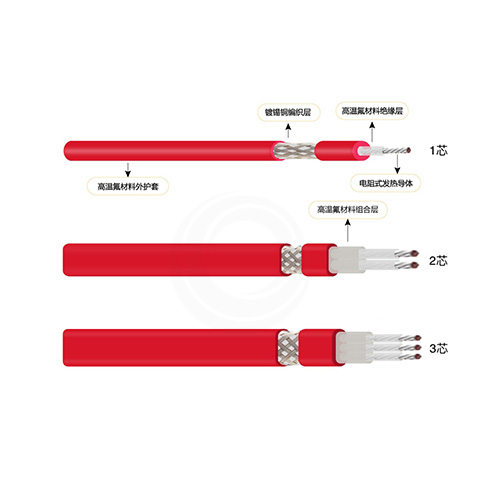

Series type constant power heat tracing cable, resistance wire is connected in series, when the pipeline is heated by the resistance wire, the core wire with a certain internal resistance will generate joule heat, and its size is proportional to the square of the current, core wire block and power-on time. Therefore, with the continuation of the power time, the series heat tracing cable continuously emits heat, forming a continuous, uniform heating of the heating cable.

Series constant power heat tracing cable is a new type of heat tracing products, it is compared with other heating cable, its biggest feature is the use of long length, its use length is the general constant power, self- control hearing cable maximum length of 5~12 times. Therefore, it is especially suitable for petroleum, chemical, electric power, port and other industries of long transport pipelines, large tanks, oil tanks and other antifreeze, insulation and heat tracking, with other explosion-proof Accessories, can be used for class II anti-explosive gas occasions.

| 1 Core Structure Series Constant Power Heat Tracing Cable (common specification table) | |||||

| Model Specification | Core structure | Supply voltage | Power/ meter | Length | Nominal cross-section range of heating core |

| TEL1-220 | 1 Core | 220VAC | 10W/m | 100m~1000m | 1.0mm 2 ~3.8mm 2 |

| TEL1-220 | 1 Core | 220VAC | 20W/m | 100m~1000m | 1.0mm 2 ~7.5mm 2 |

| TEL1-220 | 1 Core | 220VAC | 30W/m | 100m~1000m | 1.0mm 2 ~11mm 2 |

| TEL1-380 | 1 Core | 380VAC | 10W/m | 100m~1000m | 1.0mm 2 ~1.3mm 2 |

| TEL1-380 | 1 Core | 380VAC | 20W/m | 100m~1000m | 1.0mm 2 ~2.58mm 2 |

| TEL1-380 | 1 Core | 380VAC | 30W/m | 100m~1000m | 1.0mm 2 ~3.8mm 2 |

| 2 Cores Structure Series Constant Power Heat Tracing Cable (common specification table) | |||||

| Model Specification | Core structure | Supply voltage | Power/ meter | Length | Nominal cross-section range of heating core |

| TEL2-220 | 2 Core | 220VAC | 10W/m | 50m~400m | 1.0mm 2 ~1.2mm 2 |

| TEL2-220 | 2 Core | 220VAC | 20W/m | 50m~400m | 1.0mm 2 ~2.4mm 2 |

| TEL2-220 | 2 Core | 220VAC | 30W/m | 50m~400m | 1.0mm 2 ~3.5mm 2 |

| 3 Cores Structure Series Constant Power Heat Tracing Cable (common specification table) | |||||

| Model Specification | Core structure | Supply voltage | Power/ meter | Length | Nominal cross-section range of heating core |

| TEL3-380 | 3 Core | 380VAC | 10W/m | 100m~1000m | 1.0mm 2 ~1.3mm 2 |

| TEL3-380 | 3 Core | 380VAC | 20W/m | 100m~1000m | 1.0mm 2 ~2.5mm 2 |

| TEL3-380 | 3 Core | 380VAC | 30W/m | 100m~1000m | 1.0mm 2 ~3.8mm 2 |