HOMETECH☰

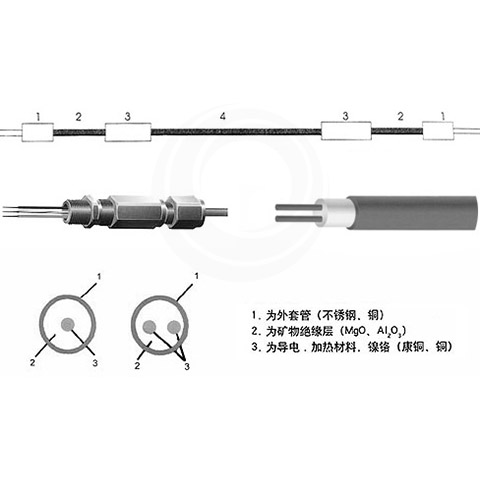

Mineral Insulated Metal-Sheathed Cable is a solid body with high density formed by multiple drawings of electric heating alloy wire (Heating Element), inorganic mineral insulation and metal casing. It can meet the needs of high temperature conditions and large heating power (up to 250W/m), and the maximum temperature can reach 600°C; the conductor resistance value ranges from 0.002Ω/m to 36Ω/m, and has excellent mechanical strength and corrosion resistance. Mainly used in nuclear industry, construction industry, metal manufacturing industry, tank and container heating, High-Temperature Industrial pipeline heating, process medium anti-condensation and viscosity reduction, various industrial Electric Heaters, etc. It has been proven in international use for more than four decades.

MI cable is a cable that uses metal (such as copper, copper-Nickel Alloy, etc.) as the conductor, Magnesium Oxide mineral insulation material as the insulator, and metal materials (such as copper, copper-nickel, stainless steel, alloy materials) as the sheath. If necessary, a layer of plastic outer sheath or low-smoke Chimney-less outer sheath can be extruded outside the metal sheath.

It can meet the needs of high temperature conditions and long-distance tubeline heating. The maximum withstand temperature can reach 250℃; for occasions requiring anti-corrosion or buried applications, a high-density polyethylene HDPE outer sheath must be added, the maximum withstand temperature can reach 90℃; and it has excellent mechanical strength.

Copper-nickel sheathed series mineral insulated cables can meet the needs of high temperature conditions and long-distance tubeline heating. Its maximum temperature can reach 400℃; mineral insulated cable has excellent mechanical strength and corrosion resistance.

Stainless steel sheathed series mineral insulated cables can meet the needs of high temperature conditions and large heating power (up to 269W/m). This series of cables can withstand a maximum temperature of 650°C; the mineral insulated cables have excellent mechanical strength and are corrosion-resistant.

The 825 all-gold sheathed series of mineral insulated cables can meet the needs of high temperature conditions and large heating power (up to 269W/m). This series of cables can withstand a maximum temperature of up to 800°C; the conductor resistance ranges from mineral insulated cables to excellent mechanical strength, high temperature resistance and corrosion resistance, and is suitable for various explosion-proof occasions and special areas.

| Model | Name | Nominal Section (mm 2) ) |

| MI/TT | Copper sheathed tube, copper core cable | 0.4-20 |

| MI/TK | Copper sheathed tube, constantan core cable | 0.4-20 |

| MI/GT | Stainless steel sheathed, copper core cable | 0.4-20 |

| MI/GK | Stainless steel sheathed, constantan core cable | 0.4-20 |

| MI/GN | Stainless steel sheath, chrome 20 nickel 80 core cable | 0.4-20 |

| Model | Specification (mm²) | Sheath Thickness (mm) | Insulation Thickness (mm) | Finished Product Outer Diameter (mm) | Maximum Length of Single Root (m) | Pressure Resistant (V) | Operating Temperature (℃) | Maximum Current (A) |

| MI/TT MI/TK MI/GT MI/GK MI/GN | 0.4 | 0.39 | 0.65 | 3.0 | 300-350 | 1500 | 250-800 | 23 |

| 0.7 | 0.38 | 0.70 | 3.2 | 280-320 | 1500 | 250-800 | 32 | |

| 1.0 | 0.385 | 0.75 | 3.5 | 250-320 | 150n | 250-800 | 41 | |

| 1.5 | 0.420 | 0.85 | 4.0 | 200-250 | 1500 | 250-800 | 50 | |

| 2.5 | 0.460 | 0.9 | 5.0 | 100-200 | 1500 | 250-800 | 67 | |

| 4.0 | 0.50 | 1.0 | 6.0 | 100-150 | 1500 | 250-800 | 75 | |

| 6.0 | 0.85 | 1.5 | 8.0 | 50-80 | 1500 | 250-800 | 90 | |

| 8.0 | 1.10 | 2.0 | 10 | 30-50 | 1500 | 250-800 | 100 | |

| 10 | 1.25 | 2.3 | 12 | 20-30 | 1500 | 250-800 | 120 |

| Parameter | Copper core copper sleeve structure | Constantan core copper nickel sleeve structure | Nickel chromium stainless steel sleeve structure | |

| Heating Power(W/m) | 5-30 | 20-100 | 50-250 | |

| Max. Surface Temperature (℃) | 200 | 400 | 650 | |

| Max. Operating Temperature(℃) | 150 | 350 | 500 | |

| Outer Diameter (mm) | Single Core | φ3-6 | φ3.5-6 | φ3.5-6.5 |

| Twin Core | φ6-10 | φ6-11 | φ5.5-11 | |

| Material(mm) | Conducting Core | Oxygen-free Copper | Constantan, PVC Alloy | Nichrome |

| Insulation Materials | Magnesium Oxide Powder | Magnesium Oxide Powder | Magnesium Oxide Powder | |

| Metal Sheath | Electrical Pure Copper | Copper-nickel Alloy | Stainless Steel | |

| Normal Temperature 20℃ Resistance per meter( Ω/m) | Cable OD (mm) | Maximum length without joints (m) |

| 2.50 | 3.5 | 340 |

| 1.60 | 3.5 | 340 |

| 1.00 | 4.0 | 260 |

| 0.630 | 4.5 | 200 |

| 0.400 | 5.0 | 165 |

| 0.250 | 5.3 | 150 |

| 0.630 | 4.0 | 260 |

| 0.400 | 4.0 | 260 |

| 0.250 | 4.5 | 200 |

| 0.160 | 4.0 | 260 |

| 0.063 | 4.0 | 260 |

| 0.040 | 4.0 | 260 |

| 0.025 | 4.0 | 260 |

| 0.017 | 4.0 | 260 |

| 0.011 | 5.0 | 165 |

| 0.007 | 5.3 | 150 |

| 0.004 | 6.0 | 120 |

| Normal Temperature 20℃ Resistance per meter (Ω /m) | Cable OD (mm) | Maximum length without joints (m) |

| 6.56 | 4.0 | 260 |

| 5.25 | 4.0 | 260 |

| 4.27 | 4.0 | 260 |

| 3.28 | 4.0 | 260 |

| 2.79 | 4.0 | 260 |

| 2.30 | 4.0 | 260 |

| 1.95 | 4.0 | 260 |

| 1.64 | 4.0 | 260 |

| 1.25 | 4.0 | 260 |

| 0.984 | 4.0 | 260 |

| 0.820 | 4.0 | 260 |

| 0.658 | 4.0 | 260 |

| 0.558 | 4.0 | 260 |

| 0.492 | 4.0 | 260 |

| 0.328 | 4.0 | 260 |

| 0.262 | 4.0 | 260 |

| 0.230 | 4.0 | 260 |

| 0.197 | 4.0 | 260 |

| 0.164 | 4.0 | 260 |

| 0.131 | 4.0 | 260 |

| 0.118 | 4.0 | 260 |

| 0.098 | 4.0 | 260 |

| 0.088 | 4.0 | 260 |

| 0.068 | 4.0 | 260 |

| 0.052 | 4.0 | 260 |

| 0.043 | 4.0 | 260 |

| 0.033 | 4.0 | 260 |

| 0.021 | 4.0 | 260 |

| 0.013 | 4.0 | 260 |

| 0.008 | 5.0 | 165 |

| 0.005 | 5.6 | 130 |

| 0.003 | 6.4 | 100 |

| 0.002 | 7.2 | 60 |

| Normal Temperature 20℃ Resistance per meter (Ω /m) | Cable OD (mm) | Maximum length without joints (m) |

| 10.0 | 3.2 | 400 |

| 6.3 | 3.2 | 400 |

| 4.0 | 3.2 | 400 |

| 2.5 | 3.4 | 360 |

| 1.6 | 3.6 | 320 |

| 1.0 | 3.9 | 270 |

| 0.63 | 4.3 | 220 |

| 0.40 | 4.7 | 190 |

| 0.25 | 5.3 | 150 |

| 0.16 | 6.5 | 95 |

| Normal Temperature 20℃ Resistance per meter (Ω /m) | Cable OD (mm) | Maximum length without joints (m) |

| 36.1 | 3.0 | 460 |

| 29.5 | 3.0 | 460 |

| 24.6 | 3.5 | 340 |

| 19.7 | 3.5 | 340 |

| 16.4 | 3.5 | 340 |

| 13.1 | 3.5 | 340 |

| 9.02 | 4.0 | 260 |

| 8.20 | 4.0 | 260 |

| 6.56 | 4.0 | 260 |

| 5.58 | 4.0 | 260 |

| 4.59 | 4.0 | 260 |

| 3.74 | 4.0 | 260 |

| 3.28 | 4.0 | 260 |

| 2.30 | 4.0 | 260 |

| 1.97 | 4.0 | 260 |

| 1.64 | 4.0 | 260 |

| 1.31 | 4.5 | 200 |

| 0.984 | 4.5 | 200 |

| 0.820 | 4.0 | 260 |

| 0.656 | 4.0 | 260 |

| 0.492 | 4.0 | 260 |

| 0.410 | 4.0 | 260 |

| 0.328 | 4.0 | 260 |

| 0.279 | 4.5 | 200 |

| 0.230 | 4.5 | 200 |

| 0.164 | 4.0 | 260 |

| 0.131 | 4.0 | 260 |

| 0.115 | 4.5 | 200 |

| 0.098 | 4.5 | 200 |

Because its structure is inorganic, MI heating cable has a long life, is not easy to age, and has high compressive strength. Because its outer sheath is a metal sheath, it determines that it will not age for a long time and can operate at high temperatures for a long time. Therefore, MI cable mineral insulated high temperature heating cable has absolute advantages.

In short, mineral insulated cables have incomparable advantages over various heating technologies and methods used in the past in places with harsh conditions such as explosion-proof, fire-proof, waterproof, anti-corrosion, and radiation resistance, and to replace traditional steam and water heating.

Rtd and Thermocouple Sensors from MI are widely used in metal heat treatment, solid waste incinerators, sintering powder metals, firing ceramic materials, gas or oil furnaces, fuel Heat Exchangers, Box Furnaces and nuclear or hydrocarbon-based energy plants.

Container heating, process pipeline insulation, storage tank heating and insulation, crude oil pipeline wax removal and blockage removal.

Large area heating of buildings, factories, warehouses, agricultural and gardening greenhouses, constant temperature-controlled poultry breeding heating.

Mechanical equipment, airstrips, TV transmission towers, culverts, Valves, gates, transportation hub facilities, schools, hospital open-air steps, intermittent liquid Pumps. Railway tracks, track forks and other places that require heating and insulation.

Deck anti-condensation, cabin heating, fluid tube heating and insulation, and mechanical equipment insulation. Mi cable's insulation will not burn, making it ideal for applications where a fire would be catastrophic. Medical equipment, power plants, and oil rigs are examples where installing MI cables will make their operations safer.

Nuclear power plant reactor preheating, oil boiler preheater, gas device preheater. MI covered cable's metal sheath helps protect the Thermocouple Wire from oxidation when used in chemically active or humid environments. Corrosion resistance makes MI cables ideal for use in areas where failure and replacement may be hazardous or even impossible. For example, MI cables are used in nuclear power plants to monitor core temperature. It can be very dangerous if the Temperature Controller does not receive accurate readings, and repairing or replacing cables in that environment is very difficult.

The mineral filler in Mi cables provides excellent non-reactive insulation, preventing the thermocouple wires from coming into contact with each other or with corrosive substances such as oil, solvents or water. This helps ensure that the thermocouple probe remains accurate, which is critical for applications such as heat treating or sintering, where the quality of the product can be adversely affected by temperature fluctuations.

Due to mineral insulation, MI cables can operate in high temperature conditions without loss of accuracy. This makes them ideal for use in kilns, firing ceramics or heat-treating metals, or any high temperature process. MI cables maintain their accuracy even during and after exposure to high temperatures, making them ideal as thermocouple probes in these operations.